The 3D Printing Breakthrough:

Reshaping the future of dentistry

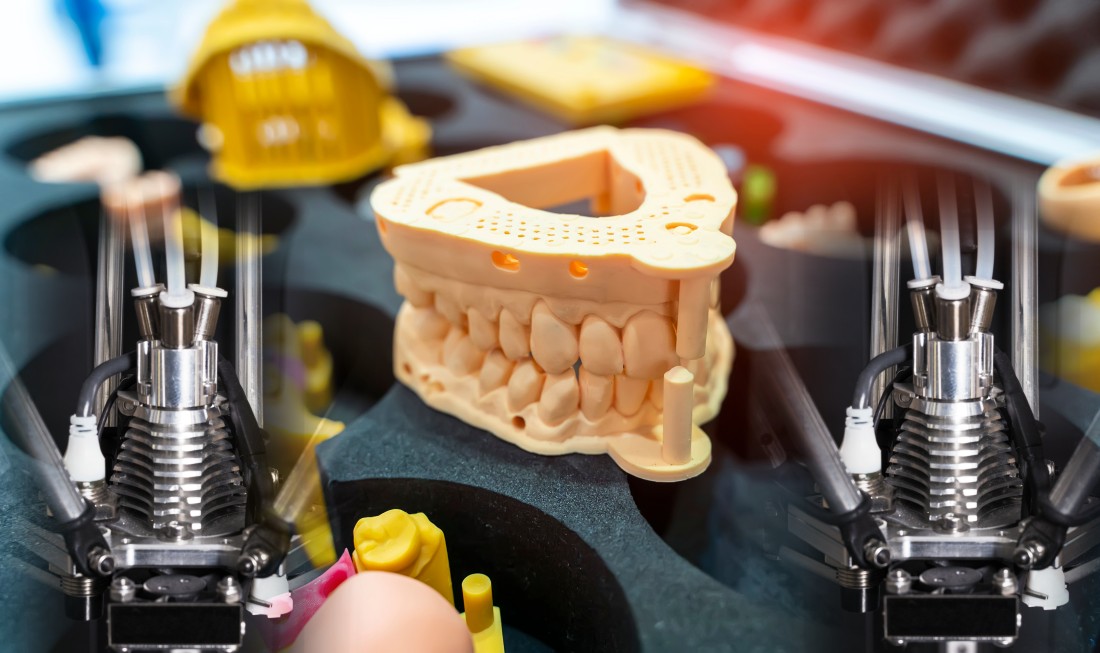

3D printing technology is transforming dentistry by creating dental models, crowns, bridges, and dentures faster and more cost-effectively, paving the way for improved patient care and accessibility.

3D printing, a technology once reserved for the realms of engineering and product design, is now making waves in the world of dentistry.

The rapid and cost-effective production of dental models, crowns, bridges, and dentures using 3D printing has the potential to revolutionise the way dental restorations and appliances are created, promising improved patient care and accessibility.

Traditionally, the fabrication of dental restorations and appliances has been a labour-intensive process, requiring skilled dental technicians to handcraft each piece.

However, with the advent of dental 3D printing, this time-consuming process can now be streamlined, making it faster and more cost-effective than ever before.

Innovation in Dentistry

Dr. Cynthia Foster, a dentist and 3D printing expert, explains the benefits of this innovative technology: "3D printing has the potential to drastically reduce the time it takes to create dental restorations and appliances, resulting in quicker treatment times for patients.

Moreover, the precision and accuracy of 3D printed restorations can lead to better fit and function, improving patient comfort and satisfaction."

The process begins with digital impressions of a patient's mouth, taken using an intraoral scanner.

These digital images are then used to create a virtual model of the patient's dentition, which can be manipulated and adjusted as needed.

Once the design is finalised, the dental restoration or appliance is printed using specialised 3D printers and materials, such as resins or ceramics.

3D Ceramic Methods

First, we have Stereolithography (SLA) and Digital Light Processing (DLP). These two methods are like siblings, both using light to cure ceramic-filled resins layer by layer. SLA employs a laser to focus on specific areas, while DLP opts for a digital projector to cure an entire layer in one go. Once the printing is done, the pieces go through debinding to remove the resin matrix, and sintering (fusing by heat) to achieve the desired properties.

Next up is Selective Laser Sintering (SLS) and Selective Laser Melting (SLM). These techniques are all about precision, using a high-power laser to fuse ceramic powders layer by layer. SLS gently heats the powder below its melting point, letting the particles fuse together, while SLM goes all in, fully melting the ceramic particles for a more uniform structure. After the laser work is done, post-processing takes care of support structures and final sintering.

Then we have Binder Jetting, which is a bit like a high-tech version of building sandcastles. It uses a liquid binding agent to glue ceramic powder particles together, layer by layer. After printing, the pieces undergo a debinding process to remove the binder, followed by sintering to achieve the right density and mechanical properties.

Finally, there's Robocasting or Direct Ink Writing, which is like 3D drawing with a ceramic paste or slurry. The ink is extruded through a nozzle, creating structures layer by layer. It's designed to hold its shape during printing, and once it's done, the piece goes through drying and sintering to reach its final form.

One of the most significant advantages of dental 3D printing is the ability to produce customised restorations and appliances that cater to each patient's unique needs.

This personalised approach can improve the overall effectiveness of dental treatments and contribute to better long-term oral health outcomes.

In addition to enhancing patient care, dental 3D printing also has the potential to increase accessibility to dental services, particularly for individuals living in remote or underserved areas.

By reducing the costs associated with traditional dental fabrication methods, 3D printing can help make dental treatments more affordable for a wider range of patients.

Despite the numerous benefits of dental 3D printing, this technology is still relatively new and continues to evolve. As Dr. Foster notes, "While 3D printing has made significant strides in recent years, there is still much research to be done to refine the materials and processes involved. However, the future of dental 3D printing is undoubtedly promising."

As 3D printing continues to advance and become more integrated into dental practice, patients can look forward to faster, more cost-effective, and personalised dental treatments, ultimately leading to better oral health outcomes and improved access to care.